Full Workshop 6

Description

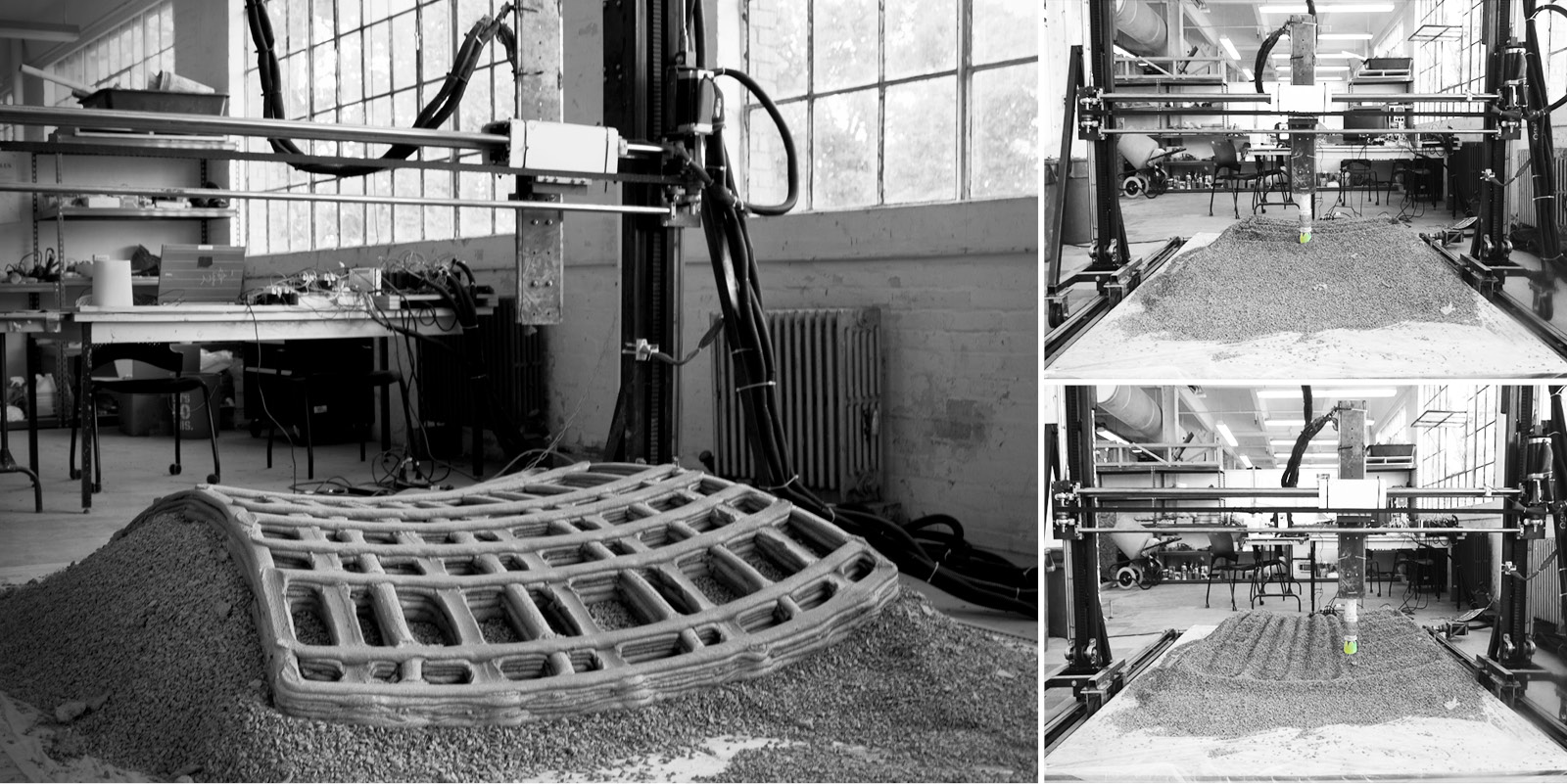

This workshop investigates new means of architectural scale concrete 3D printing to fabricate robust doubly curved geometries and construct structurally optimized thin shell structures. Sub-Additive Manufacturing explores a three dimensional deposition of concrete printing material on a mechanically shaped substructure of reusable aggregate. Concrete material is extruded with a robotic arm using three dimensionally curved deposition paths on top of the shaped gravel. By printing in three dimensions, the time consuming process of corbeling is replaced by spatial concrete arching. Creating curvature in concrete with this method increases the speed over typical 3D printing practices, can produce double curved geometries which are structurally optimized, does not require form-work during assembly of shell components, and eliminates waste material. From nozzle design and material feedback to digital form finding processes and implementation of advanced fabrication technologies, this workshop introduces a series of key concepts and methods radically advancing concrete 3D printing at full scale.

We recommend participants to attend the KUKA|prc or the HAL pre-workshop.

Instructors

Sasa Zivkovic (Cornell University, Assistant Professor), Martin Fields Miller (Cornell University, Visiting Critic), Christopher A. Battaglia (Ball State University, 2018-19 Design Innovation Fellow, Assistant Teaching Professor)

Learning goals

Participants will learn iteratively and hands-on how to design, generate, 3D print and manufacture complex lattice shell geometries using robotic fabrication tools and advanced computational structural analysis tools. Participants will get an understanding of concrete 3D-printing processes at full scale, and gain insight into potential innovations through the hacking and alteration of conventional techniques (both digitally and physically). The goal of this workshop is to convey both the potential of and challenges in 3D-printed concrete construction: operating with a palette of readily available standard construction materials, Sub-Additive Manufacturing relies upon the implementation of advanced robotics, computational technologies, novel material processes and techniques to create an elegantly simple means of fabricating complex form and structurally optimized architecture.

Requirements

- Knowledge of Rhino

- Basic knowledge of Grasshopper

- Basic knowledge of Kangaroo or Karamba (recommended)

Duration

3 days

Number of participants

16